Understanding Die Casting Mold and Plastic Mold: An In-Depth Overview

Producing enterprises depend intensely on molds for making parts with accuracy, effectiveness, and consistency. Two noticeable kinds of molds utilized broadly across different areas are Die Casting mold and plastic mold. Regardless of sharing normal standards of framing materials into explicit shapes, these molds fill various needs, are produced using various materials, and include interesting cycles. Understanding the qualifications and benefits of each can assist producers with concluding which form type best suits their requirements.

What is Die Casting?

Die casting Mold is a metal projecting cycle that includes infusing liquid metal under high tension into a steel shape or pass on. The metal sets rapidly, and the pass on is opened to eliminate the completed part. Bite the dust projecting is basically utilized for delivering non-ferrous metal parts, like aluminum, zinc, and magnesium parts. The cycle is known for its capacity to make complex shapes with high accuracy and phenomenal surface completions.

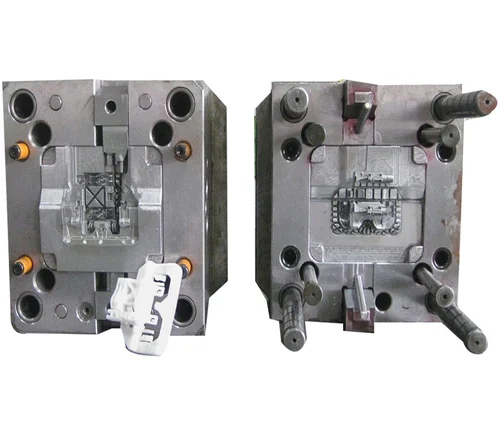

Die Casting Molds: Design and Materials

- Material Arrangement: Die casting Mold, otherwise called Die casting Mold, are produced using high-grade steel. This material is picked for its sturdiness and capacity to endure outrageous temperatures and high-pressure conditions. The shape material should oppose warm weariness, erosion, and scraped spot because of the rehashed openness to liquid metal and the fast cooling cycles.

- Plan Qualities: A pass on projecting mold commonly comprises of two parts — the fixed half, known as the “cover kick the bucket,” and the moving half, alluded to as the “ejector bite the dust.” The form configuration incorporates different elements like pits, centers, and ejector sticks, which are all designed to shape the eventual outcome, launch it easily, and keep up with high precision.

- Cooling Framework: A basic piece of the form configuration is the cooling framework. As liquid metal is infused into the shape, it should be cooled quickly and equally to guarantee that the end result keeps up with its layered dependability and surface quality. This is accomplished through worked in cooling channels that course water or oil all through the shape.

Types of Die Casting Mold

- Hot Chamber Die casting Mold: The most appropriate for metals with low liquefying focuses, similar to zinc and magnesium. The liquid metal is held inside a chamber associated with the shape, diminishing the time expected to infuse the metal into the form and speeding up.

- Cold Chamber Die casting Mold: Utilized for metals with high liquefying focuses, like aluminum and copper. In this cycle, the liquid metal is emptied physically or naturally into a chamber and afterward infused into the form. Cold chamber molds are intended to deal with the additional warm pressure brought about by higher temperatures.

Advantages of Die Casting Molds

- High Accuracy and Precision: Bite the dust projecting molds take into consideration the creation of parts with tight resistances and complex calculations. This accuracy limits the requirement for optional activities like machining.

- Sturdy and Enduring: Produced using high-grade steel, bite the dust projecting molds are intended for life span and can endure rehashed use in high-strain and high-temperature conditions.

- Fast Creation Rates: The cycle considers speedy cycles, empowering makers to deliver huge amounts of parts in a brief time frame, which is great for large scale manufacturing.

Applications of Die Casting Molds

Die casting molds are widely used in the automotive, aerospace, electronics, and consumer goods industries. They produce parts like engine components, housings, brackets, and gears that require high strength, dimensional accuracy, and excellent surface finish.

What is Plastic Molding?

Plastic Mold includes forming plastic into wanted structures by dissolving the plastic material and emptying or infusing it into a shape. The plastic then cools and solidifies, taking on the form’s shape. There are a few sorts of plastic trim strategies, including infusion forming, blow embellishment, and pressure shaping.

Plastic Molds: Plan and Materials

- Material Creation: Plastic mold are regularly produced using steel or aluminum. Steel molds are utilized for high-volume creation because of their strength and capacity to deal with high temperatures, while aluminum molds are utilized for lower-volume creation and prototyping because of their expense adequacy and quicker machining abilities.

- Configuration Elements: A plastic shape is by and large made out of two primary parts: the “center” and the “pit.” These parts are painstakingly intended to guarantee the plastic streams uniformly all through the form, staying away from deserts like distorting or voids. The plan incorporates highlights like entryways, sprinters, and vents to control the stream and cooling of the plastic material.

- Cooling Framework: Like pass on projecting molds, plastic molds have cooling frameworks that course water or oil to guarantee in any event, cooling of the plastic part. The speed and consistency of cooling straightforwardly influence the quality and layered security of the end result.

Types of Plastic Mold

- Infusion Shape: The most well-known type, utilized in infusion forming, where dissolved plastic is infused into the form under high tension. Infusion molds can deliver profoundly perplexing and exact parts in enormous volumes, making them reasonable for auto parts, clinical gadgets, shopper hardware, and bundling.

- Blow Molds: Utilized in blow shaping, a cycle where warmed plastic is ventured into a form depression by blowing air into it, making empty parts like jugs, compartments, and tanks.

- Pressure Molds: Includes putting a plastic material in a warmed shape, which is then compacted to frame the ideal shape. This technique is utilized for delivering enormous, level parts like car boards and electrical parts.

Benefits of Plastic Molds

- Flexibility: Plastic molds can deliver parts in a great many shapes, sizes, and intricacies, from straightforward compartments to complicated clinical gadgets.

- Savvy for Enormous Volumes: The underlying expense of plastic molds can be high, yet the expense per unit diminishes fundamentally with huge creation runs, making them monetarily feasible for large scale manufacturing.

- Lightweight and Solid Items: Plastic embellishment considers the making of lightweight parts that offer high strength, adaptability, and protection from synthetic substances and erosion.

Utilizations of Plastic Molds

Plastic molds are generally utilized in businesses, for example, car, bundling, medical services, hardware, and shopper products. They produce things like plastic jugs, compartments, car dashboards, clinical needles, and electronic lodgings.

Key Contrasts Between Kick the bucket Projecting Molds and Plastic Molds

- Material Utilized: Kick the bucket projecting molds handle metals like aluminum, zinc, and magnesium, while plastic molds are intended for thermoplastic and thermosetting polymers.

- Process Temperature: Kick the bucket projecting includes a lot higher temperatures than plastic embellishment because of the need to dissolve metals. Therefore, bite the dust projecting molds should be more hearty and impervious to warm weakness.

- Cost Contemplations: The underlying expense of pass on projecting molds is commonly higher because of the utilization of high-grade steel and the intricacy of the form. Nonetheless, both form types offer expense benefits in huge scope creation runs.

- Creation Speed: Kick the bucket projecting can accomplish quick creation rates, particularly with hot chamber processes, while plastic infusion shaping likewise offers high velocity creation with the additional benefit of delivering lightweight parts.

- Application Extension: Kick the bucket projecting is leaned toward for parts that require high strength, solidness, and protection from wear, for example, car and aviation parts. Plastic embellishment is great for delivering lightweight, erosion safe parts across different ventures like bundling, medical care, and purchaser merchandise.

End

Die Casting Mold and plastic mold assume vital parts in present day fabricating, empowering the development of a huge swath of parts and items. Kick the bucket projecting molds offer unrivaled strength, toughness, and accuracy for metal parts, while plastic mold give adaptability, cost-viability, and flexibility for many plastic items. Understanding the distinctions between these shape types assists makers with picking the right interaction for their particular requirements, advancing creation effectiveness, cost, and quality.