Model Railroad Wiring: Common Rail vs Common Wire Systems

Introduction

Model railroad enthusiasts know that choosing the right wiring system can make or break their layout’s performance. Two popular approaches dominate the hobby: model rr common rail vs common wire systems. Each method offers distinct advantages and presents unique challenges that can significantly impact your layout’s functionality, maintenance requirements, and overall success.

The wiring system you select will influence everything from initial setup costs to long-term troubleshooting ease. Many beginners assume all wiring methods are essentially the same, but experienced modelers understand that this foundational decision affects every aspect of their railroad’s operation. Whether you’re planning your first layout or considering an upgrade to an existing system, understanding these two approaches will help you make an informed choice.

This comprehensive guide examines both systems in detail, comparing their strengths and weaknesses across multiple criteria. By the end, you’ll have the knowledge needed to select the wiring method that best suits your specific layout requirements, technical skills, and budget constraints.

Understanding Common Rail Wiring

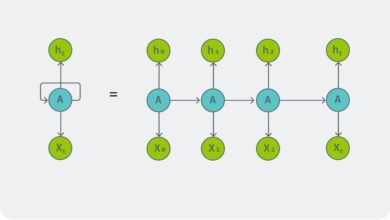

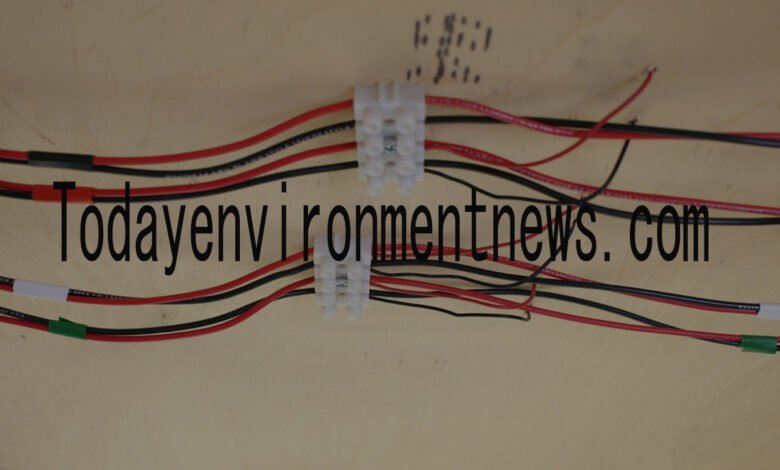

Common rail wiring represents one of the most widely adopted electrical systems in model railroading. This method involves connecting one rail continuously throughout the entire layout, creating a shared electrical pathway that serves as the return circuit for all trains and accessories.

The system works by establishing a single, unbroken connection along one rail of your track. Typically, modelers choose the outside rail for this purpose, though the inside rail works equally well. This continuous connection eliminates the need to wire both rails at every track joint, simplifying the initial installation process considerably.

Power districts become easier to manage with common rail systems because you only need to control the “hot” rail’s power supply. When multiple power sources are required for larger layouts, the common rail remains connected while separate feeders supply different sections of the hot rail. This arrangement allows for independent control of various layout sections without complex switching mechanisms.

Advantages of Common Rail Systems

The primary benefit of common rail wiring lies in its simplicity during installation. With only one rail requiring continuous electrical connections, you’ll spend significantly less time soldering feeders and ensuring proper connectivity. This time savings becomes particularly valuable on larger layouts where hundreds of connections might otherwise be necessary.

Troubleshooting electrical problems becomes more straightforward with common rail systems. When issues arise, you can focus your diagnostic efforts on the hot rail and its associated feeders, rather than checking both rails throughout the affected area. This targeted approach speeds up problem resolution and reduces frustration during maintenance sessions.

Cost savings represent another compelling advantage. The reduced number of wire runs and connections translates to lower material costs, especially on extensive layouts. You’ll need roughly half the feeder wires compared to common wire systems, making this approach budget-friendly for modelers working with financial constraints.

Disadvantages of Common Rail Systems

Despite its advantages, common rail wiring presents certain limitations that may concern some modelers. The most significant drawback involves potential ground loops and electrical interference. Since the common rail connects throughout the entire layout, electrical noise from one section can propagate to other areas, potentially affecting sensitive electronic components like decoders and detection circuits.

Reverse loops and wye tracks require special attention with common rail systems. These track configurations create electrical shorts that must be managed through gap cutting and specialized electronics. While solutions exist, they add complexity and cost to layouts incorporating these popular track arrangements.

Some advanced control systems work less effectively with common rail wiring. Certain detection circuits and computerized control systems prefer or require isolated rail sections that common rail systems cannot easily provide. This limitation may restrict your future upgrade options.

Exploring Common Wire Wiring

Common wire wiring takes a different approach by maintaining separate electrical feeds to both rails while connecting them through a shared return wire beneath the layout. This method preserves electrical isolation between rails while providing the benefits of a common return path.

The system operates by running individual feeders from both rails to a common distribution point below the layout. At this central location, one side of each rail connection joins a shared return wire, while the other sides connect to their respective power sources. This arrangement maintains the electrical separation needed for certain control systems while simplifying the overall wiring scheme.

Power management becomes more flexible with common wire systems because each rail maintains its independence throughout the layout. This separation allows for more sophisticated control schemes and better compatibility with advanced detection and automation systems.

Advantages of Common Wire Systems

The greatest strength of common wire wiring lies in its compatibility with advanced control systems. Many computerized layout control systems, occupancy detectors, and signal systems work more reliably when rails maintain electrical separation. This compatibility ensures your layout remains upgradeable as new technologies emerge.

Electrical isolation between rails eliminates many ground loop problems that can plague common rail systems. Each rail section maintains its electrical independence, preventing noise and interference from spreading throughout the layout. This isolation proves particularly valuable when using sensitive electronic equipment.

Reverse loops and complex track work become easier to manage with common wire systems. The inherent rail separation eliminates many of the shorting issues that complicate common rail installations, reducing the need for special electronics and complex gap cutting.

Disadvantages of Common Wire Systems

The primary drawback of common wire wiring involves increased installation complexity. Every rail joint requires attention to maintain proper electrical continuity, effectively doubling the number of connections compared to common rail systems. This additional work translates to longer installation times and higher labor requirements.

Material costs run higher with common wire systems due to the increased number of feeders and connections required. You’ll need roughly twice as many wire runs, connectors, and terminal strips compared to common rail installations. These additional materials can significantly impact project budgets, especially on larger layouts.

Troubleshooting becomes more complex when problems arise. With twice as many connections to check, identifying the source of electrical issues requires more systematic testing and greater attention to detail. This complexity can frustrate beginners who lack experience with electrical diagnosis.

Common Rail vs Common Wire: A Detailed Comparison

Wiring Complexity

Common rail systems clearly win in terms of installation simplicity. With feeders required for only one rail, the total number of connections drops by approximately 50% compared to common wire systems. This reduction significantly decreases installation time and reduces opportunities for wiring errors.

Common wire systems demand more careful planning and execution during installation. Every track joint must receive attention to maintain proper electrical continuity on both rails. While this attention to detail results in more robust electrical connections, it also requires greater skill and patience from the installer.

Cost Considerations

Material costs favor common rail systems due to their reduced wire and connector requirements. A typical layout might save 30-40% on wiring materials by choosing common rail over common wire systems. These savings become more pronounced on larger layouts where hundreds of connections are involved.

However, cost considerations extend beyond initial materials. Common wire systems may reduce long-term troubleshooting and maintenance costs due to their superior electrical isolation characteristics. The time saved during problem diagnosis could offset the higher initial material investment.

Scalability

Both systems scale reasonably well to larger layouts, but each presents different challenges as size increases. Common rail systems maintain their simplicity advantage regardless of layout size, making them attractive for extensive model railroads where installation time becomes a major factor.

Common wire systems become more complex as layouts grow, but their superior electrical characteristics often justify the additional effort on larger installations. The electrical isolation benefits become more valuable as the number of trains, detection circuits, and control systems increases.

Ease of Troubleshooting

Common rail systems offer simpler troubleshooting procedures because problems typically involve only the hot rail and its associated components. Diagnostic procedures become more straightforward, requiring less systematic testing to identify problem areas.

Common wire systems require more methodical troubleshooting approaches due to the increased number of potential failure points. However, the electrical isolation between rails often helps localize problems more effectively, preventing issues from affecting unrelated layout sections.

Which System Should You Choose?

Several factors should influence your decision between common rail and common wire systems. Layout size plays a crucial role, with common rail systems offering greater advantages on smaller layouts where simplicity outweighs advanced features.

Your technical expertise level significantly impacts which system will work best for your situation. Beginners often find common rail systems more forgiving and easier to implement successfully, while experienced modelers may prefer the flexibility and advanced capabilities of common wire systems.

Budget considerations extend beyond initial costs to include long-term maintenance and upgrade potential. While common rail systems cost less initially, common wire systems may provide better value if you plan to incorporate advanced control systems or frequently modify your layout.

Future expansion plans should also influence your decision. If you anticipate adding computerized control systems, extensive signaling, or complex automation, common wire systems provide better compatibility with these advanced features.

The type of operations you plan affects system suitability as well. Simple continuous running operations work well with either system, while complex switching operations and multiple train control often benefit from common wire systems’ superior electrical isolation.

Frequently Asked Questions

Can I convert from one system to the other later?

Converting between systems is possible but requires significant rewiring work. Moving from common rail to common wire systems involves adding feeders to the previously unfed rail throughout the layout. Converting from common wire to common rail requires removing feeders from one rail and ensuring the remaining rail maintains proper continuity. Both conversions represent major undertakings best avoided through careful initial planning.

Do certain track brands work better with one system?

Most modern track systems work equally well with either wiring approach. However, some sectional track systems with built-in electrical connections may favor one method over the other. Research your chosen track system’s electrical characteristics before finalizing your wiring approach.

How do digital command control systems affect the choice?

Digital Command Control (DCC) systems work well with both wiring methods, but each presents different advantages. Common rail systems simplify DCC installation and reduce initial costs, while common wire systems provide better compatibility with advanced DCC features like detection and automation. Your specific DCC system and planned features should influence your decision.

What about mixing both systems on the same layout?

While technically possible, mixing wiring systems on a single layout creates unnecessary complexity and potential compatibility issues. Choose one system and implement it consistently throughout your layout for best results.

Making the Right Choice for Your Layout

Selecting between common rail and common wire systems ultimately depends on balancing your specific requirements against each method’s strengths and limitations. Common rail systems excel in simplicity and cost-effectiveness, making them ideal for beginners and budget-conscious modelers who prioritize straightforward operations.

Common wire systems shine when advanced features, future expandability, and electrical isolation take priority over initial simplicity. These systems provide the foundation needed for sophisticated control systems and complex operations that many experienced modelers eventually desire.

Consider starting with common rail systems if you’re new to model railroading or working with limited budgets and technical experience. The simplified installation and lower costs allow you to focus on other aspects of layout construction while gaining experience with model railroad operations.

Choose common wire systems if you have the technical skills and budget to handle the increased complexity, especially if you plan to incorporate advanced control features or frequently modify your layout configuration. The long-term benefits often justify the additional initial effort and expense.