Evaluating Space Requirements for Powder Coating Booth Installation

Installing a powder coating booth is a significant investment that can vastly improve the efficiency and quality of your coating process. Proper planning is crucial to ensure that the installation goes smoothly and that the booth operates optimally. This guide will help you evaluate the space requirements for your powder coating booth installation, covering key aspects such as airflow, electrical needs, equipment placement, lighting, dimensions, and safety measures.

Determining Airflow and Ventilation Needs

Effective airflow and ventilation are critical for powder coating booths to ensure a clean and safe environment. Proper ventilation helps to remove airborne particles and fumes, preventing contamination and health hazards. When evaluating your space, consider the direction of airflow, the location of intake and exhaust fans, and the type of filtration system required. The booth should be positioned in a way that allows for optimal air circulation, reducing the risk of overspray and maintaining a consistent temperature and humidity level. This not only ensures a high-quality finish but also extends the life of your equipment and protects the health of your workers.

Assessing Electrical Power Requirements

Powder coating booths, paint spray booths, and blast booths all require substantial electrical power to operate efficiently. It’s essential to assess the electrical power requirements before installation. This involves determining the total power load of all equipment, including lights, fans, heating elements, and any additional machinery. Ensure that your facility’s electrical system can handle the load and that there are sufficient outlets and circuits available. Consulting with an electrician to evaluate the current wiring and make necessary upgrades can prevent future power issues and ensure a smooth operation from day one.

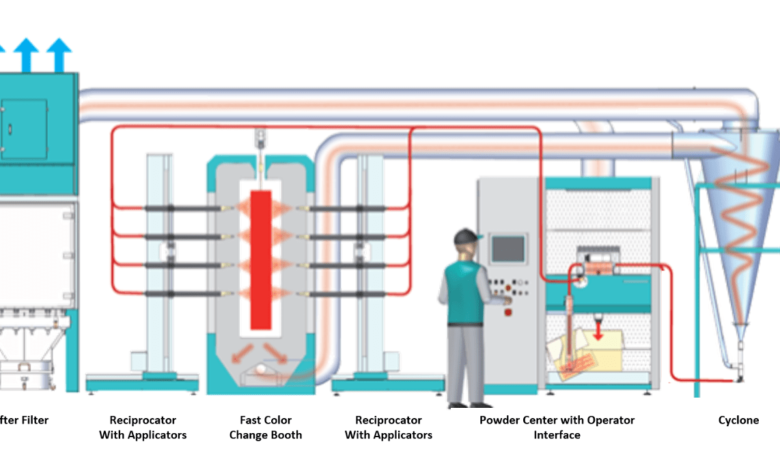

Analyzing Space for Equipment Placement and Accessibility

Proper placement of equipment within your powder coating booth is crucial for operational efficiency and safety. Evaluate the space to ensure that there is adequate room for all necessary equipment, such as spray guns, hoppers, and recovery systems. Consider the workflow and how operators will move around the booth. There should be enough space to perform tasks comfortably and safely without obstruction. Accessibility is also key; ensure that equipment is easy to reach for maintenance and cleaning. This minimizes downtime and helps maintain a smooth production process.

Evaluating Space for Proper Lighting Installation

Good lighting is essential in a powder coating booth to ensure that coatings are applied evenly and defects are easily spotted. When evaluating your space, consider the placement and type of lighting that will provide the best visibility. Ensure that the lighting layout eliminates shadows and provides even illumination across all surfaces. Proper lighting not only improves the quality of the finished product but also enhances the safety and comfort of workers operating within the booth.

Calculating Dimensions for Proper Booth Size

Selecting the right size for your powder coating booth is a critical step in the planning process. The booth needs to be large enough to accommodate the items you are coating, as well as allow for efficient workflow and ventilation. Calculate the dimensions based on the size of the largest items you will be working with, adding extra space for movement and equipment. It’s also important to consider future growth; having a slightly larger booth than currently necessary can save costs and hassle in the long run. Ensuring the booth fits well within your facility while leaving room for other operations is key to a successful installation.

Considering Safety Clearance and Fire Prevention Measures

Safety should always be a top priority when installing a powder coating booth. Adequate clearance around the booth is necessary to prevent accidents and ensure compliance with safety regulations. This includes having enough space for workers to move safely and for emergency exits to be easily accessible. Fire prevention measures are also crucial, as powder coating involves flammable materials. Ensure that the booth is equipped with proper fire suppression systems and that fire extinguishers are readily available. Regular safety audits and adherence to industry standards can help mitigate risks and create a safe working environment.

By carefully evaluating these space requirements, you can ensure that your powder coating booth, paint spray booth, or blast booth is installed efficiently and operates effectively. Proper planning not only enhances the quality of your coating process but also ensures the safety and well-being of your workers. Taking the time to assess and address these factors will lead to a successful installation and long-term operational success.