Air Compressor Bleeder Valve: Your Complete Guide

Introduction

Air compressors are powerful tools that make countless tasks easier, from inflating tires to powering pneumatic equipment. But without proper maintenance and safety measures, they can become inefficient or even dangerous. One small but crucial component that every air compressor owner should understand is the bleeder valve.

If you’ve ever wondered about that small valve on your air compressor tank or questioned how to safely release pressure from your system, you’re in the right place. This guide will walk you through everything you need to know about air compressor bleeder valves, from their basic function to proper maintenance techniques.

Understanding how to use and maintain your bleeder valve properly can extend your compressor’s lifespan, improve its performance, and most importantly, keep you safe while operating it.

What is an Air Compressor Bleeder Valve?

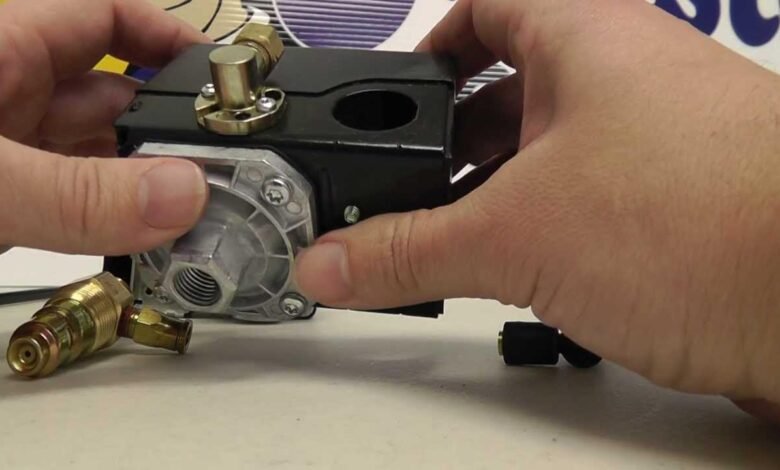

An air compressor bleeder valve is a small but essential safety component designed to release compressed air from your tank in a controlled manner. Also known as a drain valve or petcock valve, this device allows you to manually discharge pressure from the system when needed.

The valve typically consists of a threaded body with a removable plug or lever mechanism. When opened, it creates a pathway for compressed air to escape from the tank, reducing internal pressure to atmospheric levels. Most bleeder valves are located at the bottom of the air tank, making them easily accessible for regular use.

These valves come in different styles, including quarter-turn ball valves, needle valves, and simple threaded plugs. Regardless of the design, their primary function remains the same: providing a safe and controlled method to release compressed air from your system.

Why Use a Bleeder Valve?

Safety First

The most critical reason to use a bleeder valve is safety. Compressed air systems can store significant amounts of energy, and releasing this pressure improperly can result in serious injury. A bleeder valve provides a controlled release mechanism that eliminates the risk of sudden, unexpected pressure discharge.

Moisture Removal

Compressed air naturally contains water vapor that condenses inside the tank as the air cools. This moisture can cause rust, corrosion, and damage to your compressor’s internal components. Regular use of the bleeder valve helps remove accumulated water, protecting your investment and maintaining optimal performance.

Pressure Relief for Maintenance

Before performing any maintenance work on your air compressor, you must completely depressurize the system. The bleeder valve makes this process quick and safe, allowing you to work on your equipment without the risk of accidental pressure release.

Improved Efficiency

By removing moisture and maintaining proper pressure levels, regular use of the bleeder valve helps your compressor operate more efficiently. This can lead to reduced energy consumption and longer equipment life.

Step-by-Step Guide: How to Use Your Bleeder Valve

Before You Begin

Always ensure you’re wearing appropriate safety equipment, including safety glasses and hearing protection. Never attempt to use the bleeder valve while the compressor is running or under maximum pressure.

Step 1: Turn Off the Compressor

Switch off your air compressor and disconnect it from the power source. Allow the motor to come to a complete stop before proceeding.

Step 2: Locate the Bleeder Valve

Find the bleeder valve, which is typically positioned at the lowest point of the air tank. This location ensures maximum drainage of both air and moisture.

Step 3: Position Yourself Safely

Stand to the side of the valve opening, not directly in front of it. The escaping air can carry debris or moisture that you don’t want directed at you.

Step 4: Open the Valve Slowly

Gradually open the bleeder valve by turning it counterclockwise or activating the lever, depending on your valve type. Start with small increments to control the release rate and avoid sudden pressure discharge.

Step 5: Allow Complete Drainage

Let the valve remain open until all compressed air has escaped and the pressure gauge reads zero. You may notice water or oil draining out along with the air – this is normal and expected.

Step 6: Close the Valve

Once all pressure has been released, close the valve by turning it clockwise or returning the lever to its closed position. Ensure it’s properly sealed but avoid overtightening, which can damage the valve threads.

Essential Maintenance Tips

Daily Drainage

Make it a habit to drain your air compressor tank after each use. This simple practice prevents moisture buildup and significantly extends your compressor’s lifespan. Even if you only used the compressor briefly, some condensation likely formed inside the tank.

Weekly Inspection

Examine the bleeder valve weekly for signs of wear, corrosion, or damage. Look for cracks in the valve body, worn threads, or any signs that the valve isn’t sealing properly when closed.

Monthly Deep Clean

Once a month, remove the bleeder valve completely and clean it thoroughly. Use compressed air to blow out any debris, and inspect the threads on both the valve and tank. Apply a small amount of thread sealant when reinstalling to ensure a proper seal.

Replace When Necessary

Bleeder valves are relatively inexpensive components that should be replaced at the first sign of malfunction. A faulty valve can compromise your entire system’s safety and efficiency. Keep a spare valve on hand for quick replacement when needed.

Seasonal Considerations

If you store your air compressor during winter months, completely drain the tank and leave the bleeder valve slightly open to prevent pressure buildup from temperature changes. This prevents damage from freezing condensation.

Frequently Asked Questions

How often should I use my bleeder valve?

Use your bleeder valve after every compressor session to remove moisture and relieve pressure. This daily habit prevents corrosion and maintains optimal performance.

Can I leave the bleeder valve slightly open during operation?

Never leave the bleeder valve open while operating your compressor. This prevents proper pressure buildup and wastes energy while potentially damaging your equipment.

What should I do if my bleeder valve is stuck?

If your valve is stuck, try penetrating oil and gentle pressure. If it still won’t move, replace it immediately rather than forcing it, which could damage the tank threads.

Is it normal for water to come out of the bleeder valve?

Yes, water drainage is completely normal and expected. Compressed air contains moisture that condenses inside the tank, and removing this water is one of the valve’s primary functions.

Can I upgrade my bleeder valve to an automatic version?

Yes, automatic drain valves are available and can be convenient for frequent users. However, manual valves are generally more reliable and give you better control over the drainage process.

Keep Your Compressor Running Smoothly

Your air compressor’s bleeder valve might be small, but it plays a huge role in keeping your equipment safe, efficient, and long-lasting. By understanding how to use it properly and maintaining it regularly, you’re protecting both your investment and your safety.

Remember that consistent daily drainage is the single most important maintenance task you can perform on your air compressor. Make it part of your routine, and your compressor will reward you with years of reliable service. When in doubt, consult your owner’s manual or contact a qualified technician for assistance with valve maintenance or replacement.